Longer lifespan and less downtime

The newly developed Greif-Velox UltraRubberBellow inflatable tube offers a significant increase in lifespan. While the industry standard ranged from 2,000 to 10,000 cycles, the goal was to achieve at least 40,000 cycles. Initial tests show that Greif-Velox’s solution can reach lifespans of up to 125,000 cycles—an improvement by about 2,500%. In vacuum bagging processes, where materials are subject to a high wear and tear, an extended lifespan can lead to measurable reductions in downtime and production costs. Further, a ‘predictive maintenance’ approach helps to avoid unplanned stoppages. Until now, inflatable tubes were often operated until they flailed, which stopped the entire filling process. However, with a proactive maintenance approach, a predictive planning is now possible, which in turn increases efficiency and minimizes downtime.

Simplified handling and faster replacement

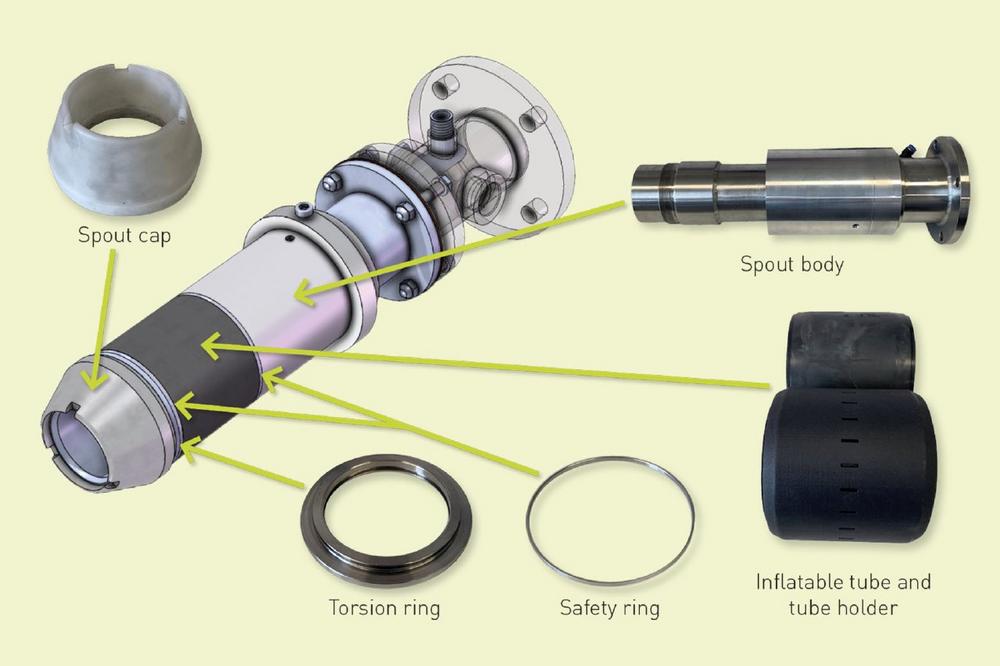

In addition to an increased lifespan, UltraRubberBellow ensures an easier handling. The optimized tube structure and the new threaded tube cap— replaced the often-adhesive screws— make replacing the inflatable tube faster and easier. These adjustments can reduce effort by up to 75%, shortening maintenance times and reducing operating costs.

Optimized materials and geometry for maximum performance

Developed through a rigorous development process, the Greif-Velox team tested various materials. By optimizing materials and geometry, they created a solution that remains highly effective even under extreme stress, such as vacuum bagging. This innovation significantly reduces unplanned failures.

Complete solution: Inflatable Tube & EasyBell

The new product is offered with the innovative EasyBell tool, providing an “easy-to-use” solution that further simplifies inflatable tube replacement and enhances operational efficiency. Customers benefit from reduced downtime, improved availability and significantly reduced maintenance costs.

Find the GREIF-VELOX website at www.greif-velox.com.

GREIF-VELOX Maschinenfabrik GmbH (www.greif-velox.com/en/) sets global standards in the packaging machinery sector and is on track to becoming a technology leader in the industry. The company designs and implements innovative bagging and filling machines with a constant focus on maximizing efficiency for its clients. Among its groundbreaking products is the VeloVac gross vacuum packer, revolutionizing the bagging process for ultra-light powders. The product portfolio also includes palletizing robots, enabling complete full-line solutions. Driven by customer needs, GREIF-VELOX continuously develops new systems and patents that provide sustainable solutions to long-standing industry challenges. With nearly 1,000 years of company history, GREIF-VELOX has consistently demonstrated its core values: Efficiency, Innovation, and Reliability (EIR). Today, GREIF-VELOX Maschinenfabrik GmbH operates worldwide with over 150 experts across 89 countries. Since 2024, Sebastian Pohl and Thorsten Köll have served as managing directors.

GREIF-VELOX Maschinenfabrik GmbH

Kronsforder Landstr. 177

23560 Lübeck

Telefon: +49 (451) 5303-0

Telefax: +49 (451) 5303-233

https://www.greif-velox.com

PR

Telefon: 004945154692373

E-Mail: modrow@agenturhoch3.de

Marketing Manager

Telefon: +49 451 5303 300

E-Mail: b.voges@greif-velox.com

![]()