Details can be found in the peer-reviewed paper published in ACS Applied Engineering Materials, which is titled “Stable Operation of Copper-Protected La(FeMnSi)13Hy Regenerators in a Magnetic Cooling Unit” (https://doi.org/10.1021/acsaenm.4c00747).

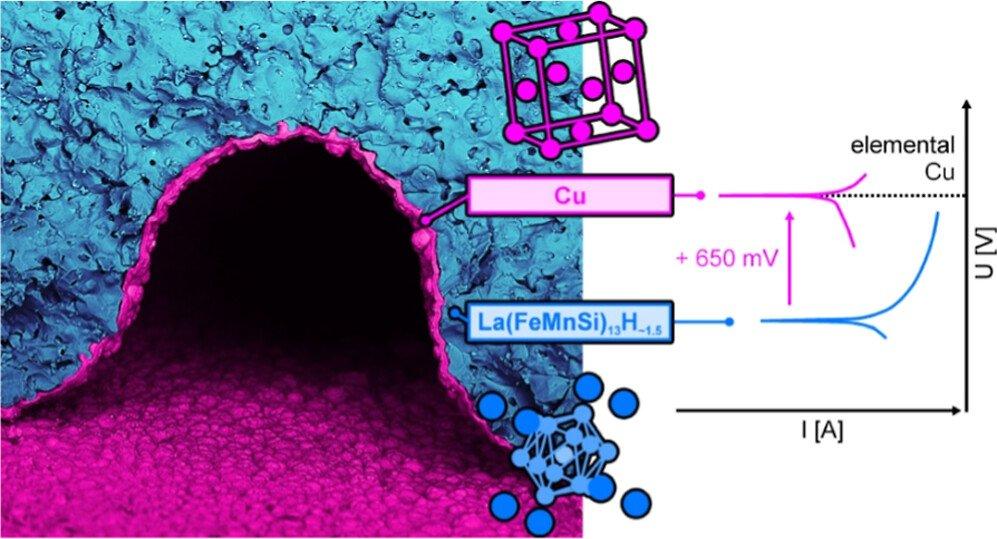

MAGNOTHERM’s machines derive their cooling power from solid-state refrigerants. To add magnetic cooling to the portfolio of available sustainable cooling technologies as a 100% safe, refrigerant-free alternative, these functional materials must be scalable, cost-efficient and enable high energy efficiencies on the device level. Lanthanum-Iron-Silicon alloys provide these characteristics, are commercially available and considered within the caloric materials family as one of the most promising alternatives to gas compression cooling, but they are also prone to corrosion and fracture. Preventing their degradation during use is pivotal to ensure reliable, maintenance friendly and performant device operation. Thus, MAGNOTHERM deems additional stabilisation mandatory for the successful commercialisation of this materials class.

The corresponding development efforts, which were led by company chemist Dr. Falk Muench and driven by Nico Weiß, Ulysse Rocabert, Cornelia Hoppe, Jens-Peter Zwick and Dr. Maximilian Fries, are showcased in the above publication. By combining MAGNOTHERM’s proprietary, cost-effective copper coating with a tailored corrosion inhibitor mixture, mechanical fracture, functional losses and corrosion alike was near completely suppressed during continuous use over three months. Initial demonstration of stable operation means that this highly performative material, known for its brittleness and corrosivity in water, has taken a major leap in magnetocaloric materials science from promising theory to successful practical application. This represents a significant step in paving the way for the broad commercial application of magnetocaloric cooling systems, which are safe, low-maintenance, and refrigerant free.

MAGNOTHERM CEO Timur Sirman says of this company milestone: “Showing that our coating process stays stable in-device underscores MAGNOTHERM’s ability to lead the way from the fundamental feasibility of magnetocalorics to actual applications. It is a huge step forward in terms of commercialization of magnetic cooling technology with a low-cost and high-performant alloy system.”

MAGNOTHERM is a leading innovator in cooling technology. Founded in 2019 and headquartered in Darmstadt, Germany, MAGNOTHERM’s team of over 30 experts are committed to transforming bold ideas into tangible, cost-saving realities.

MAGNOTHERM Solutions GmbH

Pfungstädter Str. 102

64297 Darmstadt

Telefon: +49 (6151) 7803920

http://www.magnotherm.com

Marketing Managerin

E-Mail: press@magnotherm.com

![]()