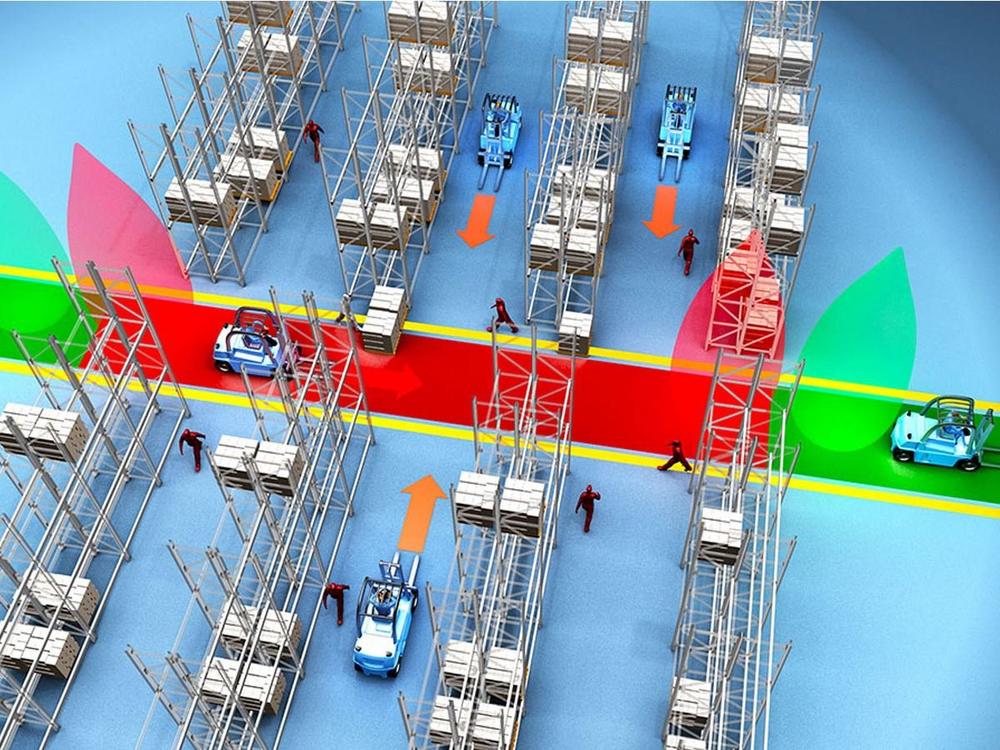

Collisions between vehicles itself, between vehicles and pedestrians or collisions between vehicles and gates or other operating equipment are a real cost factor.

This is where the NoColl collision protection system (NoColl stands for ‘no collision’) from Munich-based tbm hightech control GmbH comes in to prevent them. It is based on intelligent communication between the sensors on the vehicle and sensors on the traffic route, gates, road sections or entire company areas and zones. In short, the sensors contribute to road safety by indicating dangerous situations and locations to the vehicles and intervening directly in the driving function, e.g. by reducing speed.

The main cause of collisions and damage in intralogistics – as in public road traffic – is ‘inappropriate speed’. In logistics, however, the NoColl system automatically reduces speed without the driver being able to avoid it. It slows the vehicles down at the relevant points and only allows them to return to full speed once the vehicle has passed the danger zone.

Safety is the key issue

In terms of safety, NoColl clearly stands out from the ‘crowd of assistance systems’. According to DIN EN ISO 13849-1 (Safety of machinery), the NoColl Dome V2 fulfils performance level c . This is the standard for the design of safety-related parts for control systems according to which the NoColl Dome is constructed and designed. With the usual driver assistance systems available on the market, this is an unrivalled level of safety.

The vehicle equipment is quite simple. It consists of mounting the NoColl Dome V2 on the cab roof, which is both a transmitter and receiver of the coded infrared signals with which the system communicates with the NoColl Dome V2 on the traffic routes. This communication makes the NoColl Dome an incredibly flexible and versatile collision protection system

The NoColl Dome V2

… for gate protection

However, the NoColl Dome V2 delivers its intelligent performance when it is supplied with information about vehicle conditions by the vehicle. It then only brakes the vehicle, e.g. when driving onto a gate, if the vehicle mast is raised too high and therefore does not fit through the gate.

This means that a vehicle’s speed is not reduced every time it drives onto the gate, but only if there is an imminent danger due to the lifted mast. When the vehicle mast is lowered, the vehicle can drive through the door without being affected.

The NoColl Dome V2 at the gate checks whether the gate is fully open and passes this information on to the vehicle. This intelligent communication not only ensures an accelerated material flow but also that the door is not hit.

… for area safety

The NoColl Dome V2 is not only used for gate protection, but also for entire zone and area protection when it is necessary to limit the speed of a vehicle within an entire company area. The switchover usually takes place when entering this area and is released again when leaving the area. A light signal on the NoColl Dome V2 indicates that the vehicle is ‘limited by NoColl’.

… for speed adjustment in certain zones

NoColl sensors limit the speed on a section of road defined by you, e.g. in a zone where pedestrians are frequently travelling or at bottlenecks. This prevents obstructive one-way traffic.

… for traffic control

NoColl is also used to control the flow of traffic within intralogistics. NoColl prevents defined vehicles from entering an area into which they are not allowed to drive, e.g. due to sprinkler systems and therefore insufficient ceiling height. To do this, they are stopped at the entrance by a NoColl dome on the building structure and are forced to leave the entrance in reverse.

…

… for speed adjustment in the event of traffic encounters

On traffic routes where vehicles only meet with a small side distance, the NoColl Dome V3 ensures that the speed of the vehicles is automatically reduced during the encounter, allowing them to pass each other safely.

These numerous examples show the many possible applications of NoColl technology within intralogistics to increase safety at traffic routes.

This makes the NoColl system the most frequently used collision protection system. Well over 3,000 vehicles from all manufacturers have already been equipped with it

Halle 10 Stand B05

tbm hightech control GmbH

Karl-Hammerschmidt-Str. 32

85609 Aschheim b. München

Telefon: +49 (89) 6700360

Telefax: +49 (89) 6379172

http://www.tbm.biz

Marketing

Telefon: +49 (89) 67003620

E-Mail: edgar.nassal@tbm.biz

![]()