A research project conducted by the University of Giessen in 2006-2008 determined this prevention success from an empirical and theoretical point of view and calculated a commercial figure, the return on prevention (RoP), i.e. the ratio of prevention benefits to prevention costs of 2.2. This means that an investment in prevention measures, particularly in the areas of transport, production and warehousing, pays for itself with more than double the amount. Occupational safety has been repositioned as a result. Assistance systems are now part of a modern forklift truck. Analysing the benefits of an assistance system is a central element of a modern management system, not least because the benefits can be ‘experienced’.

More and more providers

In addition to the ‘well-known’ providers of assistance systems, there are more and more start-ups, newcomers and vehicle manufacturers appearing on the market, making it increasingly difficult for interested parties to find the right solution and make a decision.

In this growing field of providers, one company stands out that has been developing safety and protective equipment for intralogistics for over 30 years. The company tbm hightech control GmbH from Aschheim near Munich. Back in 1989, it launched the first mobile personal protection device for high-bay vehicles, which is now a standard feature of this type of vehicle equipment. ‘We have been familiar with market developments in this area for over 30 years and have seen many ideas come and go,’ says Edgar Nassal (former Managing Director of tbm) ’The consistent further development and improvement of our individual products reflects the noticeable change in protection and safety systems in intralogistics. This results in a very long product life cycle for our solutions’

Assistance systems vs safety systems

Assistance systems for forklift trucks are generally not considered to be safety systems. This is because assistance systems do not comply with DIN EN ISO 13849-1 (Safety of machinery – General principles for safety-related parts of control systems).

However, there is a clear trend that not only is technology evolving, but customer requirements are also becoming more demanding. As a result, safety-related aspects are also increasingly being taken into account in assistance systems.

The safest rear area warning system

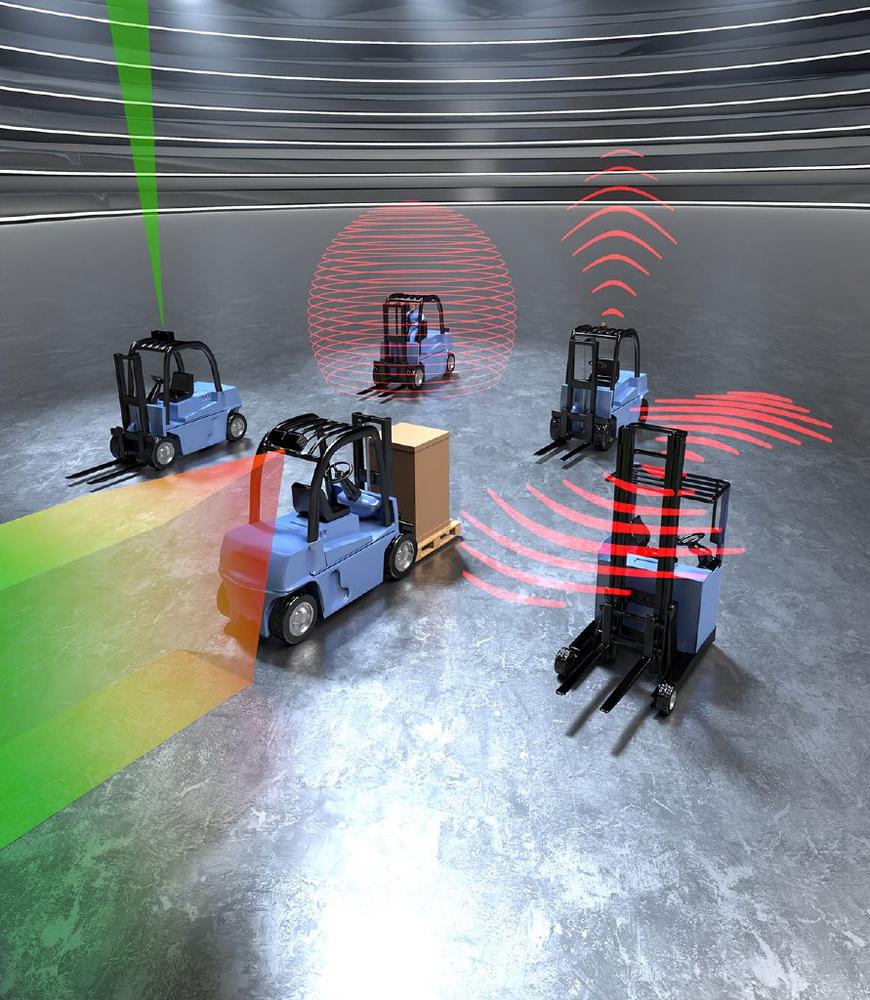

This is demonstrated by an example from the tbm hightech control GmbH range. For many years, a RRW-107 rear area warning device was used to prevent accidents involving people when reversing forklift trucks. This was based on ultrasonic technology with special ultrasonic sensors that covered the reversing area.

By changing the technology used, tbm hightech control has taken the step of launching the first and only RRW-207 reversing warning device on the market that works with the safest radar technology. With the unique safety radar sensor and special control electronics for use with forklift trucks, the overall system achieves performance level c in accordance with DIN EN ISO 13849-1 – a safety level previously unrivalled in the field of assistance systems.

This is the second system in tbm’s product range that fulfils PL c. This is the NoColl collision protection system, which has been in use for years and prevents collisions between forklift trucks or automatically reduces the speed of intralogistics vehicles in certain zones, areas or on individual routes, thus ensuring an economical, fast and, last but not least, safe material flow.

Find out more at LogiMAT 2025 Hall 10; Stand B05 and at www.tbm.biz

tbm hightech control GmbH

Karl-Hammerschmidt-Str. 32

85609 Aschheim b. München

Telefon: +49 (89) 6700360

Telefax: +49 (89) 6379172

http://www.tbm.biz

Marketing

Telefon: +49 (89) 67003620

E-Mail: edgar.nassal@tbm.biz

![]()