Extremely water-repellent or superhydrophobic surfaces offer many advantages. They are used, for example, in shipbuilding or in pipe systems to minimize friction with water or other liquids.

Another exciting application relates to an everyday problem and comes from the automotive sector. When it is cold outside, drivers can often be seen pulling hard on the doors; this can lead to increased friction or even blockage of the locking system on car doors due to the formation of ice between the metal frame and the moving parts. Here too, superhydrophobic (SHP) surfaces can prevent this ice formation. However, the coating quickly loses its effectiveness in this area of application or simply wears off over time due to the heavy use and corresponding load.

A project team has joined forces to overcome this challenge. The SKZ Plastics Center is cooperating with the Fraunhofer Institute for Applied Polymer Research, Carl Bechem GmbH and 4D Concepts GmbH to develop an SHP surface with a sustainable and long-lasting effect to prevent the formation of ice on the moving parts of locking systems, among other things.

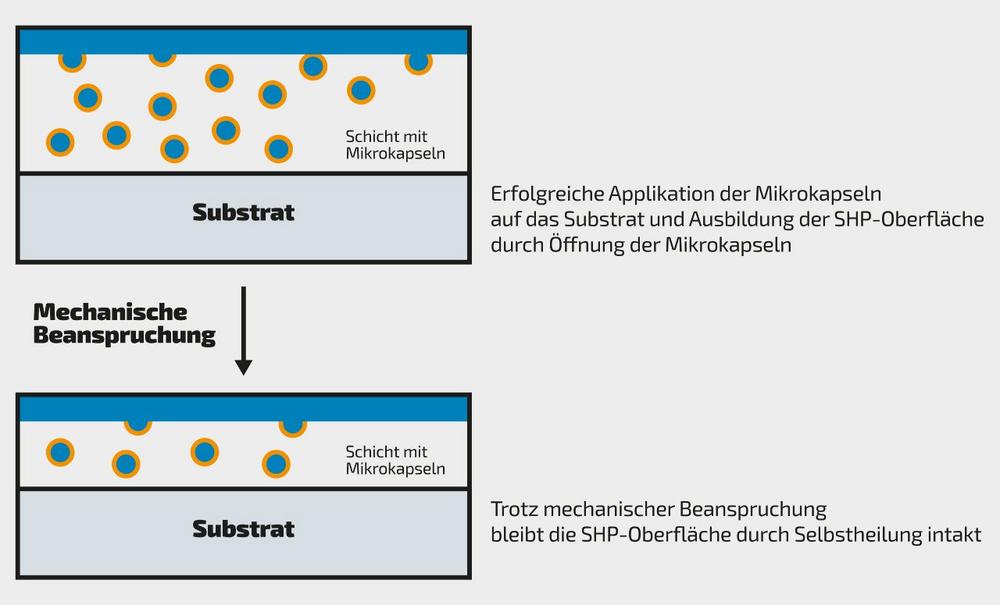

“Our approach is to develop a coating with microcapsules that are filled with a superhydrophobic substance and applied directly to the material, causing the layer to renew itself again and again. This would make the component more durable and also more resource-efficient, as recurring external application to the surface would no longer be necessary,” explains Patrick Limbach, Senior Engineer at SKZ.

By integrating microcapsules into plastic compounds, various property improvements can be achieved in components. The SKZ Plastics Center already has extensive experience with the development and incorporation of microcapsules into plastic systems from other research projects. If the research project, which was launched in September 2024 and is planned to run until 2027, is successful, additional applications for self-regenerating SHP surfaces are conceivable. Wherever tribologically stressed coatings are used outdoors, the development can bring benefits.

Examples include roller shutters or external roller blinds, where icing leads to similar problems and puts a strain on the drive motor.

The SKZ is climate protection company and a member of the Zuse Association. This is an association of independent, industry-related research institutions that pursue the goal of improving the performance and competitiveness of industry, especially SMEs, through innovation and networking.

FSKZ e. V.

Friedrich-Bergius-Ring 22

97076 Würzburg

Telefon: +49 931 4104-0

https://www.skz.de

Senior Engineer | Material Development and Testing

Telefon: +49 (931) 4104-473

E-Mail: p.limbach@skz.de

![]()