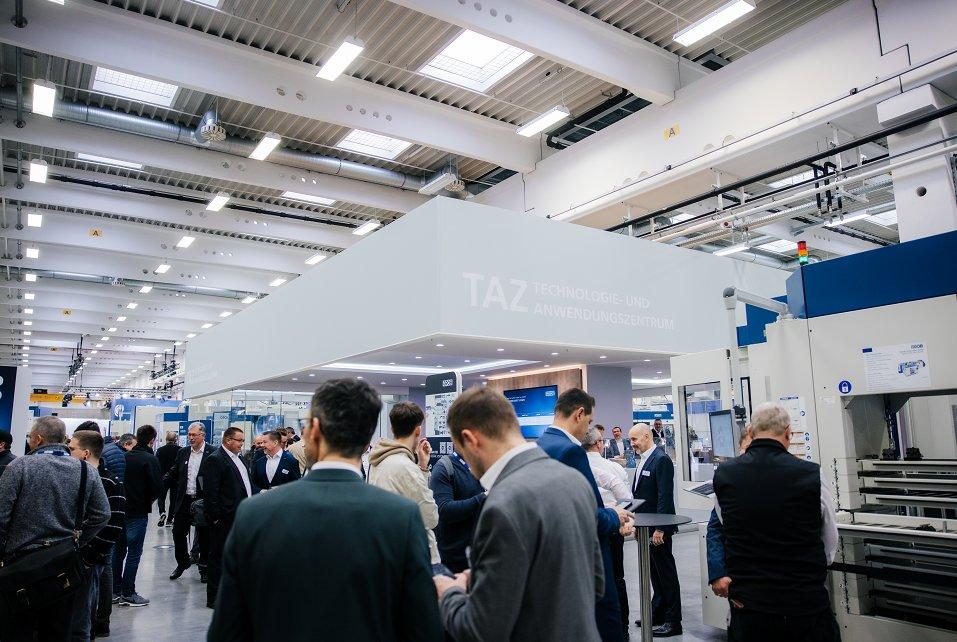

Technological highlights on over 6,000 square meters

Visitors can expect an impressive exhibition area with innovative exhibits from the fields of universal machines, automation, machining technology, additive manufacturing, digitalization, e-mobility, service and much more. GROB is focusing on an exciting mix of technology premieres, live demonstrations and factory tours.

A special highlight is the G550 5-axis universal machining center with the newly developed Vario rotary table, a special table solution for turbine parts as well as thin, slender parts. The new clamping hydraulics will also be presented on the G550T milling-turning machining center, which optimizes the automatic clamping of turned parts. The next generation of the PSS-R900 rotary pallet storage system, which impresses with even more flexibility and performance and will also be celebrating its premiere at the in-house exhibition, ensures maximum efficiency in automation.

Another impressive example of one of GROB’s many technologies in the field of additive manufacturing is the performance of the GMP300. The second generation of the machine impresses with an optimized sealing concept, real-time monitoring of droplet formation and an improved shielding gas concept for even higher component quality. In addition, a second wire feed system enables faster material changes for greater flexibility. Interested visitors can experience the GMP300 live in action.

A visit is also worthwhile for short-term machine requirements, as both new and used machines are presented and offered for sale on site. Interested parties can also find out in detail about the latest developments in GROB service.

Digitalization that impresses

Visitors can also expect something new in the area of digitalization. With GROB-NET4Industry, the Bavarian machine manufacturer is setting new standards in industrial digitalization. One particular highlight is the new GROB4PartFlow part tracking system, which enables the unique serialization of components. This allows process and production data to be assigned to an individual part – an essential advantage for modern, fully networked production systems.

Solutions for the mobility of the future

At this year’s in-house exhibition, GROB will be presenting the new G920F5 machining center, which has been specially developed for the task of mega and giga castings as well as frame structure parts. This innovation sets new standards in machining technology and offers a future-proof solution for the automotive industry.

The Bavarian machine manufacturer also has some news to report in the field of electromobility. For example, GROB is launching a new generation of the laminator and Z-folding machine – with noticeable improvements in speed, efficiency and flexibility. Thanks to an optimized laser cutting process and new web guidance, the revised Laminator 2.0 enables production speed to be doubled. At the same time, production costs and space requirements are reduced. A new interface ensures seamless integration into existing production lines. The first order has already been secured from a major car manufacturer.

The Z-folding 3.0 has also been further developed: Shorter process times significantly increase output. Standardized safety standards facilitate the handling of LFP and NMC cells, while an integrated inspection system ensures quality in real time. The system also offers greater flexibility, as the stack thickness can be adjusted directly via the HMI and optional notching can be integrated.

In addition to these innovations, GROB is also driving forward cell-to-pack technology. Here, battery cells are integrated directly into the battery housing, which reduces weight and increases energy density. This increases the range of battery electric vehicles. The scalable technology is suitable for both electric cars and stationary energy storage systems and offers great potential for the future.

At the in-house exhibition, visitors will have the opportunity to talk to experts from the field of electromobility and find out more about the various technologies. A hairpin system and stators in various development stages will also be on display to provide a practical insight into the innovative manufacturing process of this pioneering technology. In addition, interested visitors can delve even deeper into GROB’s e-mobility solutions during the numerous factory tours.

Part-Wall – a tribute to global cooperation

A special highlight of the trade fair is the workpiece wall, where typical parts from different countries – including the Eiffel Tower and other symbolic exhibits manufactured in GROB’s global application centers – are presented.The workpiece wall illustrates GROB’s global presence and emphasizes the company’s precision work.

Comprehensive exhibitor area and application options for every industry

Once again this year, the GROB in-house exhibition is cooperating with over 60 partner companies who will be presenting their latest products and solutions. The exhibitor area thus offers the unique opportunity to experience comprehensive industry solutions from a single source.

The in-house exhibition 2025 also places a strong focus on industry-specific applications, such as aerospace, mold making, mechanical engineering, energy technology, automation and automotive. Trade visitors can look forward to practice-oriented presentations and demonstrations that illustrate the wide range of possible applications for GROB technologies in these areas.

GROB-WERKE GmbH & Co. KG

Industriestr. 4

87719 Mindelheim

Telefon: +49 (8261) 996-0

Telefax: +49 (8261) 996-268

http://www.grob.de

Marketingreferentin

Telefon: +49 (8261) 996-7414

E-Mail: katharina.strohm@grob.de

![]()