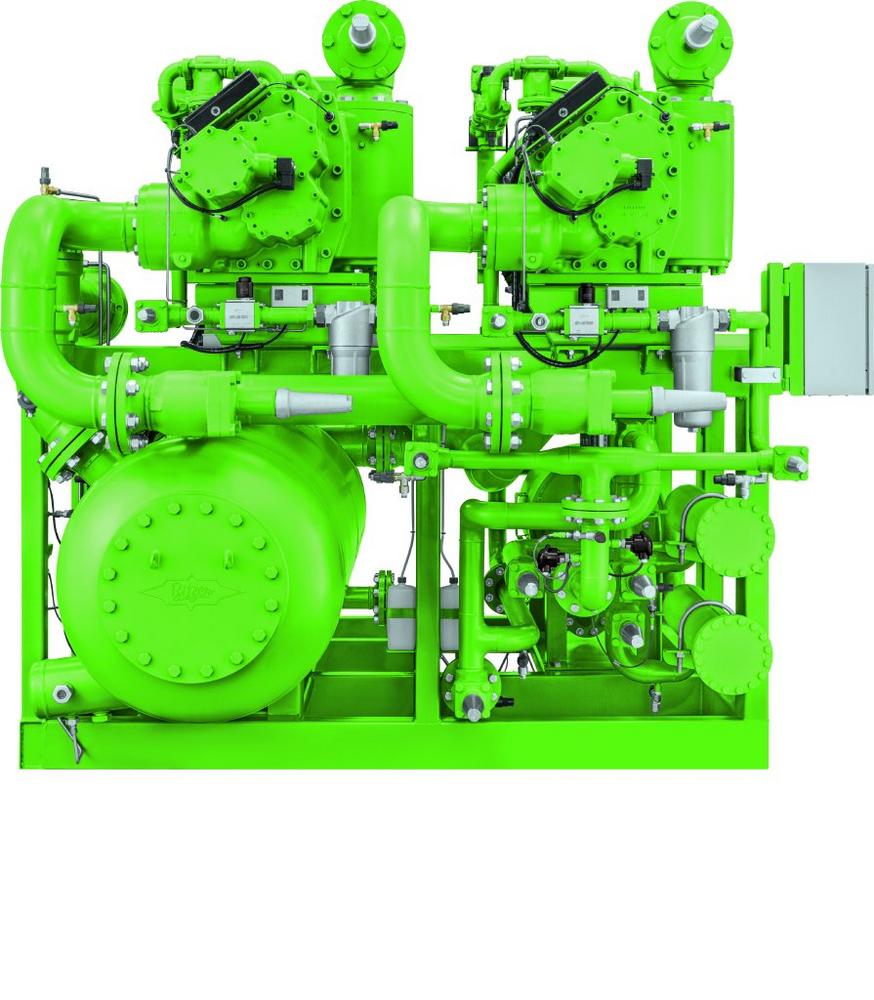

BITZER Ammonia Compressor Packs are designed to exceed the high efficiency and reliability standards of industrial refrigeration. ACP contain compressors, motors, an oil separator and an optional oil cooling circuit as well as an optional pack of controllers and frequency inverters. Some of their components like the OS.A95 screw compressor and OAHC oil separator are exhibited at BITZER’s stands at this year’s Chillventa.

Designed with a vision of providing the lowest life cycle cost to customer, each ACP can comprise up to three compressors and can achieve up to 3 MW (–10/35oC) of cooling capacity. ACP come with discharge pressure regulator as standard and a wide variety of options including an economiser.

Efficient operation

High efficiency at part-load is ensured by a multicompressor concept and intelligent capacity control of the compressors. An ACP controller in conjunction with onboard BITZER IQ technology ensures that the ACP run reliably and efficiently for the given operating condition.

Redundancy for high operating reliability

The parallel circuit of the dependable BITZER screw compressors increases operating reliability compared to industrial compressors in the same performance class. Both the controller and the most important sensors are designed with onboard redundancy and proactive control layers to increase system reliability. ACP feature exceptional starting behaviour due to their multiple compressor strategy. The starting current is reduced by approximately one-third when compared with a single compressor pack providing the same cooling capacity. This results in smaller components and lower installation costs. Monitoring the application limits with alarm and shut-off limits and operating parameters ensures maximum reliability. If the alarm limit is exceeded, the controller automatically takes countermeasures and informs the primary controller.

Durability and service

ACP are inherently service-friendly through carefully thought-out mechanical design. Additional benefits of the BITZER Ammonia Compressor Packs include fast availability of all replacement parts and durability. And, because nothing is costlier than a system being down, every compressor part can be delivered within 48 hours. Rainer Große-Kracht, Member of the Board and Chief Technology Officer at BITZER, puts it in a nutshell: ‘The biggest benefit of our ACP for customers is that they receive a fully assembled, functioning compressor unit from BITZER, which can be quickly and simply installed on-site. And they receive the high BITZER quality they already know from our components.’

■

The BITZER Group is the world’s largest independent manufacturer of refrigeration compressors. BITZER is represented across the globe through distribution companies and production facilities for reciprocating, screw and scroll compressors, heat exchangers and pressure vessels. In 2017, 3,500 employees generated sales of €740 million.

Overview of images

Images may only be used for editorial purposes. They can be used free of charge if the source is given – ‘Photo: BITZER’ – and a free copy of the publication is sent to us. Images may not be modified or altered, except to crop out the background surrounding the main subject.

BITZER Kühlmaschinenbau GmbH

Peter-Schaufler-Platz 1

71065 Sindelfingen

Telefon: +49 7031 932-0

Telefax: +49 7031 932-147

http://www.bitzer.de

Head of Public Relations

Telefon: +49 (7031) 932-4327

Fax: +49 (7031) 932543-70

E-Mail: patrick.koops@bitzer.de

![]()