Double Space Savings

When looking at the design of the single supply detector, two details become clear, which make a significant contribution towards ensuring that such a powerful solution fits into such a small space. The first detail is the central window built directly in the cap, which all other models of the series of miniaturised multi channel detectors have, too. The correspondingly large aperture of 8.5 × 8.5 mm2 means that the LRM-278 has a very large field of view (FOV). This gives rise to its outstanding signal-to-noise ratio.

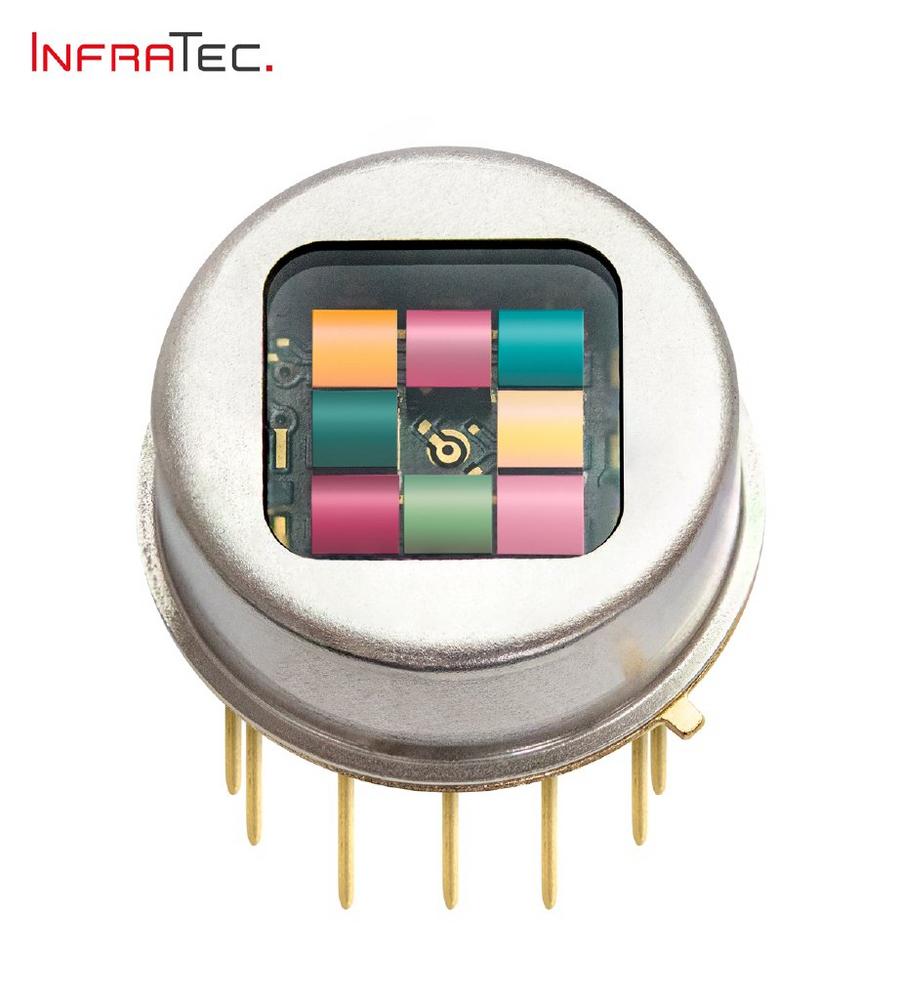

The second detail is concealed inside the detector. There, on special chip carriers, the sensitive pyroelectric sensors, the compensation elements as well as the 2 × 2 mm2 filters are positioned directly on top of each other. Due to this stack design, there is sufficient space for all other components.

Temperature Sensor Directly in the Detector

The frames with sensitive elements and filters are arranged in a square each with three times three fields. With a total of eight channels, one field thus remains free – the one in the middle. At this position there is a temperature sensor. With gas sensors, the temperature is usually measured as well. Until now, this has not been possible directly in the detector, however. Measuring the temperature inside the detector, for example, provides the option of compensating the typical temperature drift of the filters very accurately by means of a calibration.

In addition to the measurement accuracy, there are also the benefits resulting from the current mode of the LRM-278. This means that it impresses particularly by its fast displaying of signal changes and dynamic response behaviour. The resulting high signal voltage simplifies the circuit design and allows the detector to become more resilient against disturbances. The higher signal levels support the easy integration of the detector into measuring modules.

Thanks to all these benefits, the LRM-278 is predestined for extremely complex tasks within the gas analysis. This includes the analysis of medical and technical gases, the measurement of emissions as well as applications in the field of safety technology.

Die InfraTec GmbH Infrarotsensorik und Messtechnik wurde 1991 gegründet und hat ihren Stammsitz in Dresden. Das inhabergeführte Unternehmen beschäftigt mehr als 200 Mitarbeiter und verfügt über eigene Entwicklungs-, Fertigungs- und Vertriebskapazitäten.

Mit dem Geschäftsbereich Infrarot-Messtechnik zählt InfraTec zu den führenden Anbietern kommerzieller Wärmebildtechnologie. Neben der High-End-Kameraserie ImageIR® und der Produktfamilie VarioCAM® High Definition bietet das Unternehmen schlüsselfertige thermografische Automationslösungen.

Infrarot-Sensoren mit elektrisch durchstimmbaren Filtern auf MOEMS-Basis zählen neben spektral ein- und mehrkanaligen Infrarot-Detektoren zu den Produkten des Geschäftsbereiches Infrarot-Sensorik. Die Detektoren kommen z. B. bei der Gasanalyse, der Feuer- und Flammensensorik sowie der Spektroskopie zum Einsatz.

InfraTec GmbH Infrarotsensorik und Messtechnik

Gostritzer Str. 61 – 63

01217 Dresden

Telefon: +49 (351) 82876-0

Telefax: +49 (351) 82876-543

http://www.infratec.de

Telefon: +49 (351) 871-8625

Fax: +49 (351) 871-8727

E-Mail: sensor@InfraTec.de

![]()