SPECTRO’s new DSOI technology, a brand-new approach to the critical issue of plasma view design, uses a vertical plasma torch, observed via a new direct radial-view technology. Two optical interfaces capture emitted light from both sides of the plasma, using only a single extra reflection, for added sensitivity and elimination of issues plaguing newer vertical-torch dual-view models. As a result, DSOI provides twice the sensitivity of conventional radial systems and yet avoids the complexity, drawbacks, and cost of vertical dual view models.

SPECTROGREEN analysis delivers significant advantages in determining trace elements and handling samples with challenging matrices, including certain wastewaters, soils, and sludges, as well as samples containing industrial chemicals, high salts content, and metals. The SPECTROGREEN spectrometer is ideal for routine analyses in environmental and agronomy applications, as well as consumer product safety, pharmaceuticals, petrochemicals, chemicals, and foods.

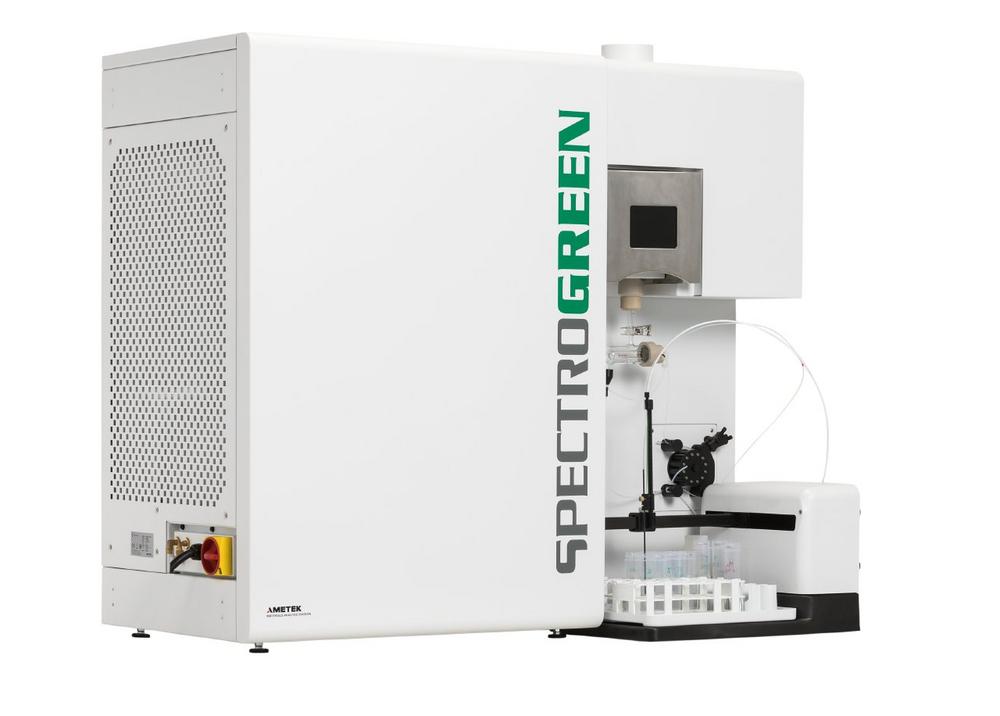

Regarding affordability, the SPECTROGREEN analyzer is both available at a competitive price/performance ratio and provides what could be the lowest operating expenses in its class. The new analyzer saves on consumables with a low-purge optic design (an innovative UV-PLUS option offers a no-purge feature) and requires no added cooling, thus eliminating the need for expensive, breakdown-prone external chillers.

Additional SPECTROGREEN analyzer features include:

- SPECTRO’s ORCA optical technology that maximizes light throughput, stability, and sensitivity

- Transparency and light throughput that provide best-in-class performance for UV elements and deliver twice the sensitivity of a conventional radial view across the whole spectral range from 165 nm to 700 nm

- Access to the entire wavelength range with a single analysis. This eliminates the need to choose a viewing mode or make multiple analyses and is a critical advantage for high-productivity laboratories

- New GigE readout system that significantly boosts spectra processing and transport speeds for faster analysis speeds, shorter sample-to-sample times, and more samples per hour.

- Thermal stabilization of the optic system without subzero cooling, as well as optimized spectral range CMOS line array technology that avoids blooming, while providing fast readout, wide dynamic range.

- The latest LDMOS 1700 W generator, which helps analyze difficult sample matrices in lower dilutions to lower limits of detection, while staying cool and trouble-free, and delivering fast warmup for higher productivity.

- A clean, compact design that makes all sample introduction components readily visible and That design offers a short, optimized fluid path and a footprint that occupies less benchtop depth than any other ICP analyzer, with space in front for a small autosampler.

- New SPECTRO ICP Analyzer Pro operating software which delivers a simply intuitive easy-to-use experience. Streamlined workflows are backed by a modular plug-in architecture to customize the interface for each user’s needs. Even with large amounts of data, processing speeds are ultrafast — up to 1500x faster than previous database systems. Version and user management, combined with excellent audit trail functionalities, make the analysis process fully transparent and traceable.

The introduction of the SPECTROGREEN spectrometer builds on more than 30 years of acknowledged innovation and unsurpassed support from SPECTRO — one of the world’s leading suppliers of analytical instruments.

SPECTRO helps ensure uninterrupted performance and maximum ROI life via unmatched AMECARE services. Machine-to-machine (M2M) support allows proactive alerts, backed up by an on-request PC connection with a remote SPECTRO service expert.

The new SPECTROGREEN analyzer is available immediately from SPECTRO Analytical Instruments. For more information, visit http://www.spectro.com/… or email spectro.info@ametek.com.

SPECTRO, a unit of the Materials Analysis Division of AMETEK, Inc., manufactures advanced instruments, develops the best solutions for elemental analysis in a broad range of applications, and provides exemplary customer service.

SPECTRO’s products are known for their superior technical capabilities that deliver measurable benefits to the customer. From its foundation in 1979 until today, more than 50,000 analytical instruments have been delivered to customers around the world.

AMETEK, Inc. is a leading global manufacturer of electronic instruments and electromechanical products, with 17,000 colleagues at 150 manufacturing and sales and service operations in 30 countries around the world.

For more information, visit http://www.spectro.com or email spectro.info@ametek.com.

Spectro Analytical Instruments GmbH

Boschstr. 10

47533 Kleve

Telefon: +49 (2821) 892-0

Telefax: +49 (2821) 892-2200

http://www.spectro.com/

Marketing Communications Coordinator

Telefon: +49 (2821) 892-2106

Fax: +49 (2821) 892-2207

E-Mail: Thorsten.Goertz@Ametek.com

Telefon: +1 (781) 793-9380

E-Mail: dgoncalves@tizinc.com

Marketing Director

Telefon: +49 (2821) 892-0

Fax: +49 (2821) 892-2200

E-Mail: spectro.info@ametek.com