The question LAPP wants answered is: Do conventional AC cables work just as well with DC? Up to now, many experts have said yes. But it’s not a dead cert, warns Professor Frank Berger from the Technical University of Ilmenau. His tests have revealed that the DC electric field has a different effect on the plastic insulation in a cable to that of an AC electric field. “It’s too early to make a conclusive recommendation,” said Professor Berger. However, he reckons it is already apparent that different materials should be used in certain DC applications compared to AC applications. It is thought that further practical tests will clarify the situation. LAPP cooperates closely with the working group and also supplies test cables and test machines.

LAPP has adapted Professor Berger’s research findings and is the first manufacturer to launch its own family of cables designed specifically for DC applications. It all started in the past year with the ÖLFLEX DC 100. Additional ÖLFLEX DC cables – genuine innovations that are unparalleled on the market – will now be revealed at Hannover Messe 2019:

ÖLFLEX® DC SERVO 700

This power cable supplies electric drives with direct current. It is suitable for occasional flexible use and fixed installation. The conductors are insulated with special PVC.

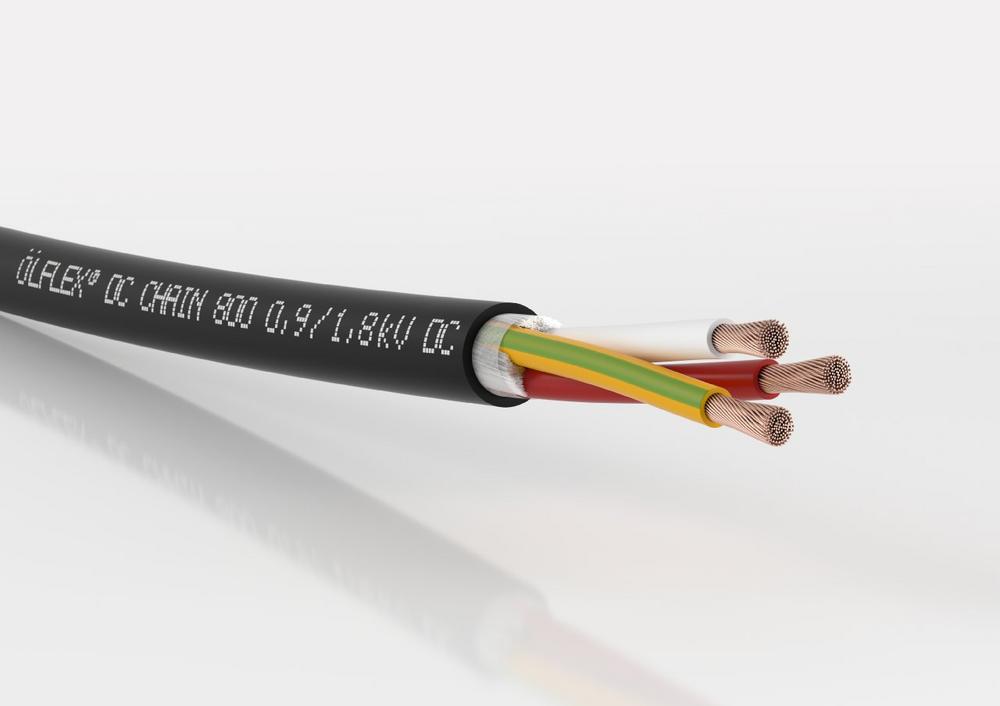

ÖLFLEX® DC CHAIN 800

This cable from LAPP’s Extended Line goes a step further. It features TPE insulation and is suitable for constant movement in cable chains and in machine parts with linear movement.

Direct current will also be one of the focal points of the Future Lab, a dedicated area at the LAPP stand that focuses on innovations in connection technology. “LAPP is a pioneer in developing cables for DC networks,” emphasised Georg Stawowy, member of the Board responsible for Technology and Innovation at LAPP Holding AG. “LAPP customers can rely on our DC cables fulfilling the same high quality standards as all other products by LAPP.”

LAPP will be showcasing its new DC cables at Hannover Messe 2019 in Hall 11, Stand C03.

Headquartered in Stuttgart, Germany, LAPP is a leading supplier of integrated solutions and branded products in the field of cable and connection technology. The company’s portfolio includes standard and highly flexible cables, industrial connectors and cable entry systems, customized system solutions, automation technology and robotics solutions for the intelligent factory of the future, as well as technical accessories. LAPP’s core market is in the industrial machinery and plant engineering sector. Other key markets are in the food industry as well as the energy and the mobility sector.

LAPP has remained in continuous family ownership since it was founded in 1959. In the 2017/18 business year, it generated consolidated revenue of 1,153 million euros. LAPP currently employs approximately 4,245 people across the world, has 18 production sites and around 44 sales companies. It also works in cooperation with around 100 foreign representatives.

U.I. Lapp GmbH

Schulze-Delitzsch-Str. 25

70565 Stuttgart

Telefon: +49 (711) 7838-01

Telefax: +49 (711) 78382640

http://www.lapp.com

Public Relations & Media

Telefon: +49 (711) 7838-5170

Fax: +49 (711) 7838-5550

E-Mail: Markus.j.mueller@lappkabel.de

Telefon: +49 (711) 7838-01

Fax: +49 (711) 7838-2640

E-Mail: irmgard.nille@in-press.de

![]()