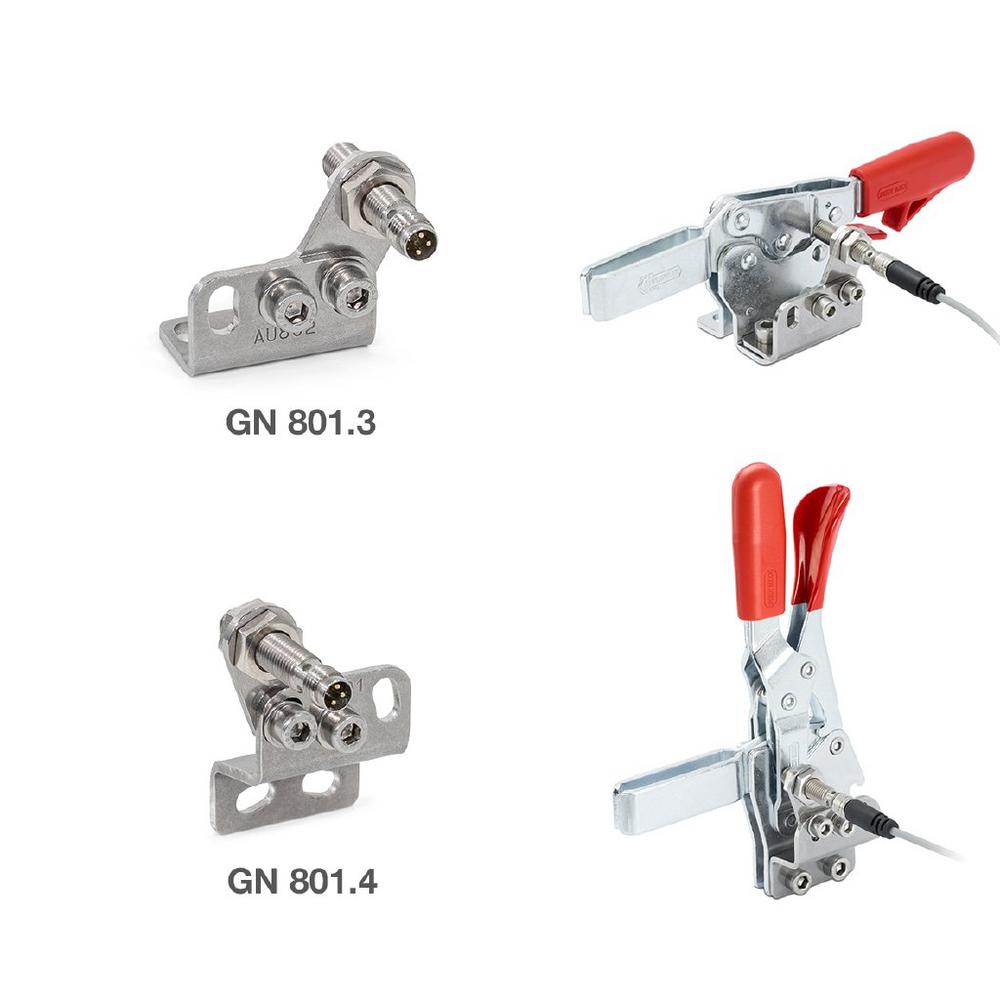

Often the most easily overlooked things turn out to be among the most useful. The sensor holders GN 801.3 and GN 801.4 are perfect examples. These add-on elements help enable position monitoring for many types of toggle clamps and therefore play an important role in process reliability.

These standard parts consist of two pieces: the retaining bracket, which is easily attached using the bores already present on the toggle clamp, and the retaining plate with the bore for the sensor itself. The plate can be quickly affixed to the bracket with setting nuts and features an elongated hole for precise adjustment of the sensor and its switching point. Because no new mounting bores are required, the sensor holder is ideal for quickly upgrading existing installations. It does not matter whether the toggle clamp is oriented vertically or horizontally, whether it has a locking lever or whether the sensor holder needs to be attached on the right or left side. This last aspect is especially worth highlighting as the position of the setting nuts can be chosen during installation to mount the sensor holder on the left or right of the toggle clamp.

The sensor holder is compatible with all typical inductive sensors with M8 thread. To make it even simpler to upgrade or build secured mechanisms, Ganter also offers the sensor holders as a complete unit including sensor. The sensor has a three-pole M8 plug, can be operated with 10-36 V direct current and indicates via LED as well as a high signal when the toggle clamp has securely arrived at the end point.

This is the case when the knee lever of the clamp has passed the so-called dead point. Sensing methods implemented in this way rule out the possibility of workpieces remaining improperly secured in partially or fully automated systems. The stability of the process is enhanced in this way, which also increases a company’s quality and economic performance.

More information on Ganter standard parts can be found on the internet at ganternorm.com

Otto Ganter GmbH & Co. KG

Triberger Str. 3

78120 Furtwangen

Telefon: +49 (7723) 6507-0

Telefax: +49 (7723) 4659

http://www.ganternorm.com

Leitung Marketing

Telefon: +49 (7723) 6507-226

Fax: +49 (7723) 6507-9226

E-Mail: axel.weber@ganter-griff.de

![]()