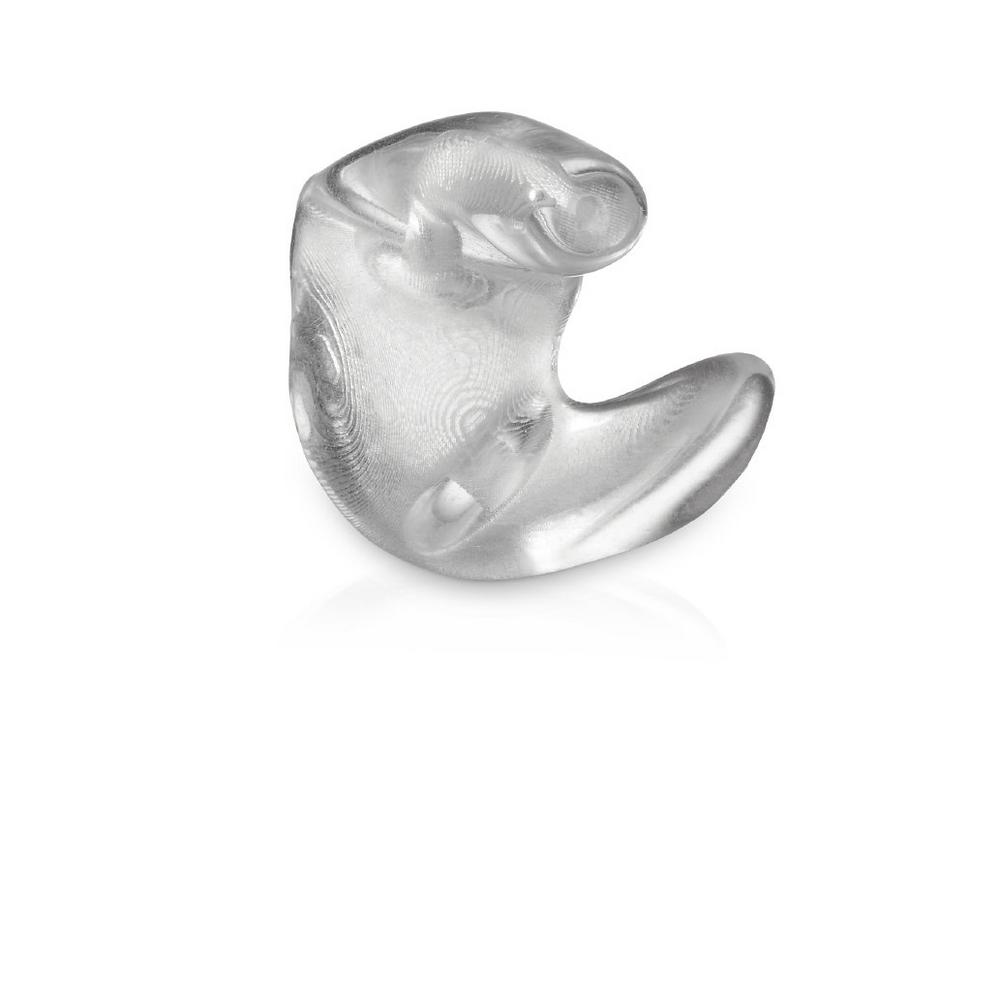

Each auricel is unique

Today’s hearing aids usually disappear almost invisibly in or behind the ear. A good, individually made earmould – also calles otoplastics – ensures that the hearing aid fits absolutely securely and almost invisibly in the auditory canal and is by no means perceived as disturbing by the wearer. The earmoulds are manufactured individually for each patient either in additive manufacturing processes or by machining. The roughness caused by the manufacturing process makes a smoothing after-treatment of the earmoulds necessary.

Gently and effective with disc finishing machines

A gentle and effective surface treatment is necessary to prevent the otoplastics from being damaged during post-treatment and to maintain the geometry precisely. Often it is not possible to do completely without manual processing as a preliminary stage for mechanical post-treatment, because internal geometries are sometimes difficult to achieve with automated processes. Effective machining in the OTEC disc finishing machine reduces manual pre- or post-machining to an absolute minimum. This saves time!

Depending on the number of parts and the initial condition, it is possible to vary between different machines, process equipment and running times. The average machining time is 1 – 2 hours per process step. Depending on the machine, larger quantities can also be processed simultaneously.

The OTEC CF series is the best choice for small series up to series production. For the manufacturer, the conversion of the process to automatic post-treatment increases efficiency. An optional coating can still be applied depending on the desired optical result, but is not a must for appearance, fit and wearing comfort.

About OTEC Präzisionsfinish

OTEC Präzisionsfinish GmbH offers precision technology for the production of perfect surfaces. Machines from OTEC for smoothing, precise edge rounding, polishing and deburring are used for economical surface finishing of a wide variety of workpieces. With a network of international trading partners, OTEC is represented worldwide and close to its customers. A wide variety of industries such as the tool industry, automotive industry, aerospace industry, medical technology as well as the watch and jewellery industry benefit from OTEC’s comprehensive know-how in the development of the perfect interplay of machine and process equipment.

Die OTEC Präzisionsfinish GmbH bietet Präzisionstechnologie für die Erzeugung perfekter Oberflächen. Maschinen von OTEC zum Glätten, präzisem Kanten verrunden, Polieren und Entgraten dienen zur rationellen Oberflächenveredlung verschiedenster Werkstücke. Mit einem Netz aus internationalen Handelspartnern ist OTEC weltweit kundennah vor Ort vertreten. Verschiedenste Branchen wie Werkzeugindustrie, Automobilindustrie, Luft- und Raumfahrt, Medizintechnik sowie die Uhren- und Schmuckbranche profitieren vom umfassenden Know-how des Technologieführers OTEC in der Entwicklung des perfekten Zusammenspiels von Maschine und Verfahrensmittel.

OTEC Präzisionsfinish GmbH

Heinrich-Hertz-Straße 24

75334 Straubenhardt

Telefon: +49 (7082) 4911-20

Telefax: +49 (7082) 4911-29

http://www.otec.de

Marketing

Telefon: +49 (7082) 4911670

Fax: +49 (7082) 4911142

E-Mail: info@otec.de

Marketing

Telefon: +49 (7082) 491125

E-Mail: c.wasserbaech@otec.de

![]()