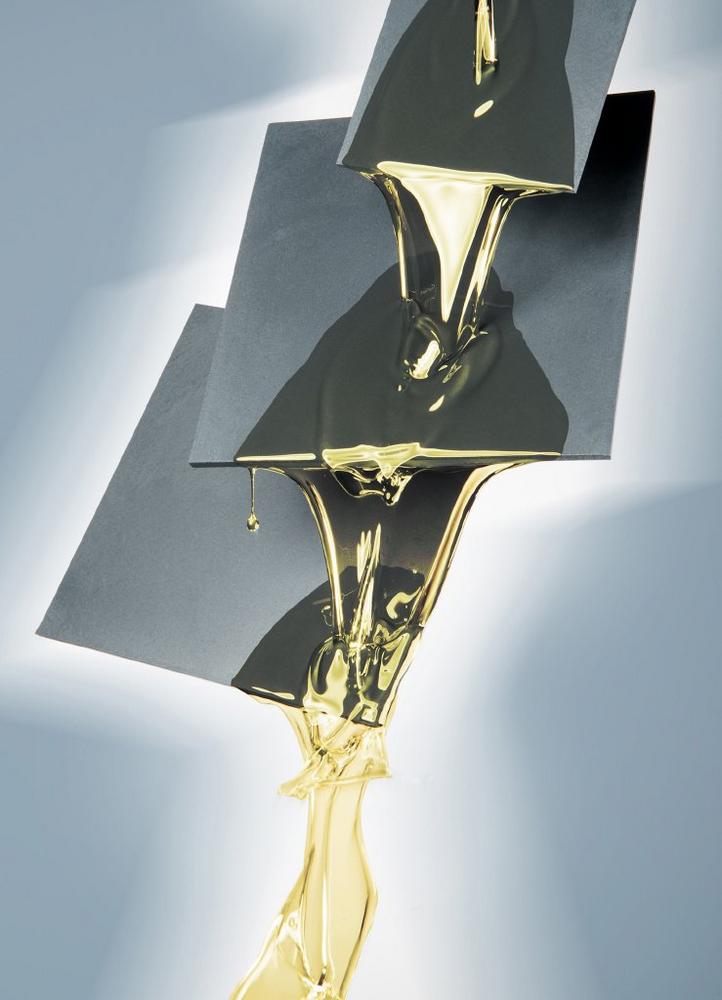

Ultrason® E0510 C2TR enables the manufacture of various car parts that come into contact with oil: oil pumps, oil control pistons, pressure valves and high-speed components in automatic or manual gearboxes. It can also be employed in new applications for alternative drive technologies. Due to its good flow properties parts with wall thicknesses of less than one millimeter can be injection-molded without compromising on their stability, durability and oil resistance. The low coefficient of thermal expansion of 10.4 [10-6/K] ensures parts that are dimensionally stable and that can withstand rapid temperature changes from cold to hot without any damages. Tests according to ASTM G137 have shown that the sliding friction performance outperforms the one of other tribologically optimized high-performance thermoplastics: even at high wear rates, test components show only low wear with virtually unchanged mechanical stability and chemical resistance.

The new material combines its tailor-made features with the proven properties of Ultrason®: extraordinary chemical resistance, inherent flame retardance, high rigidity and strength combined with temperature stability over a large operating temperature range and outstanding hydrolysis resistance.

Ultrason® is the trade name for BASF’s product range of polyethersulfone (Ultrason® E), polysulfone (Ultrason® S) and polyphenylsulfone (Ultrason® P). The high-performance material is used to manufacture lightweight components in the electronics, automotive and aerospace industries, but also in water filtration membranes and in parts that come into contact with hot water and food. Because of their extraordinary property profile the Ultrason® brands can substitute thermosets, metals and ceramics.

For more information: www.ultrason.basf.com

At BASF, we create chemistry for a sustainable future. We combine economic success with environmental protection and social responsibility. More than 117,000 employees in the BASF Group work on contributing to the success of our customers in nearly all sectors and almost every country in the world. Our portfolio is organized into six segments: Chemicals, Materials, Industrial Solutions, Surface Technologies, Nutrition & Care and Agricultural Solutions. BASF generated sales of €59 billion in 2019. BASF shares are traded on the stock exchange in Frankfurt (BAS) and as American Depositary Receipts (BASFY) in the U.S. Further information at www.basf.com.

About BASF’s Performance Materials division

BASF’s Performance Materials division encompasses the entire materials’ know-how of BASF regarding innovative, customized plastics under one roof. Globally active in four major industry sectors – transportation, construction, industrial applications and consumer goods – the division has a strong portfolio of products and services combined with deep understanding of application-oriented system solutions. Key drivers of profitability and growth are our close collaboration with customers and a clear focus on solutions. Strong capabilities in R&D provide the basis to develop innovative products and applications. In 2019, the Performance Materials division achieved global sales of €6.06 bn. More information online: www.plastics.basf.com.

BASF SE Kommunikation BASF-Gruppe

Carl-Bosch-Straße 38

67056 Ludwigshafen

Telefon: +49 (621) 60-0

Telefax: +49 (621) 60-42525

http://www.basf.com

BASF SE Kommunikation BASF-Gruppe

Telefon: +49 (621) 60-42241

Fax: +49 (621) 60-49497

E-Mail: ulla.biernat@basf.com

![]()