The non-destructive testing of laser welds is a necessary and mostly by vehicle manufacturer prescribed process within the production of control gears. With the high-performing, customized ultrasonic inspection systems, developed by VOGT Ultrasonics, the fast automated inspection of weld seams is done within the production process.

By using the bubbler technique a high cycle time and thus a short handling time is realized. Faulty welded parts are directly rejected and are not processed any further. The automated inspection, evaluation and documentation save time and create inspection reliability. Interferences during the welding process are detected within minutes.

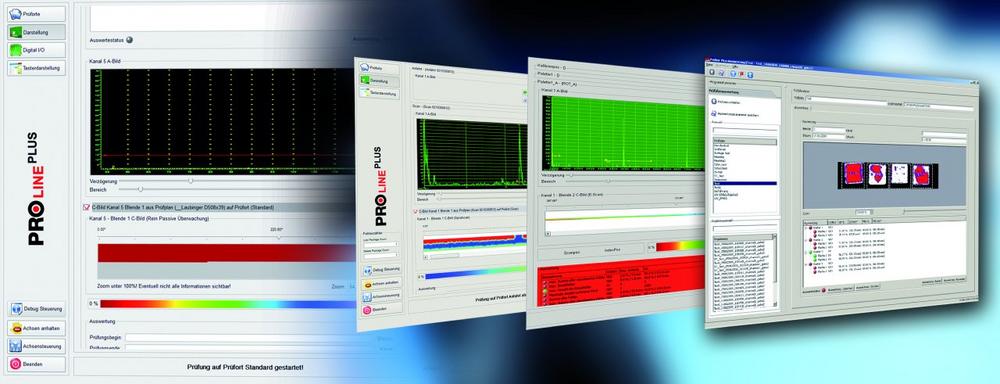

The ultrasonic inspection basin with bubbler technique is automatically loaded with a control gear by a portal. Then, the portal performs the inspection movement by a 360° rotation of the component. The scan is performed with a timeline and a C-Scan is created. The PROlinePLUS inspection and evaluation software automatically evaluates the inspection data and supplies the result to the system control (PLC) via profinet interface.

If the result is "Not OK" the inspection system automatically performs a second inspection of the component. A repeated evaluation as "Not OK" leads automatically to the re

jection of the component.

With future-oriented ultrasonic technologies and a comprehensive range of inspection services, we are your partner for non-destructive material inspection.

We develop and produce high-performance ultrasonic inspection devices and systems for inline- and offline inspection as well as OEM solutions and modernize old inspection systems with the newest ultrasonic technology. Furthermore we are a sales partner to well-known manufactures and technology partner of renowned companies. On this basis, we realize your ideal inspection solution according to your requirements and wishes.

At your site or in our testing centre in Burgwedel (Hanover), we provide all conventional nondestructive inspection services as well as mechanized and automated ultrasonic inspection solutions.

We are accredited as independent testing laboratory according to DIN EN ISO/IEC 17025 and certified according to ISO 9001 for Industry and EN 9100 for aerospace.

VOGT Ultrasonics GmbH

Ehlbeek 15

30938 Burgwedel

Telefon: +49 (5139) 9815-0

Telefax: +49 (5139) 9815-99

https://www.vogt-ultrasonics.de

Leitung Marketing

Telefon: +49 (5139) 9815-36

Fax: +49 (5139) 9815-99

E-Mail: marketing@vogt-ultrasonics.de